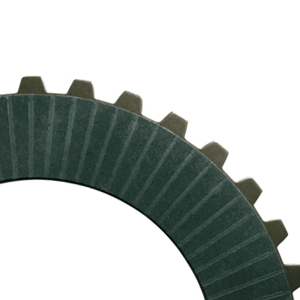

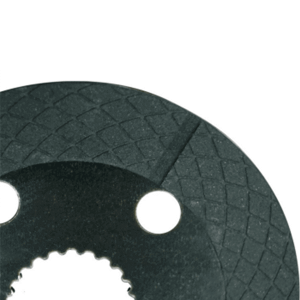

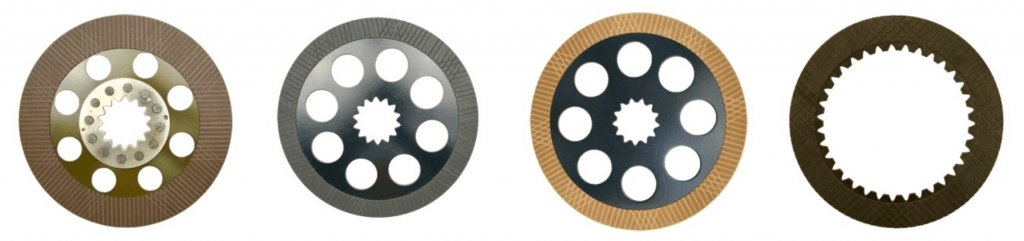

Paper Friction Disc has an enhanced structure designed to provide superior energy capability, good engagement characteristic, low wear and long service life. Paper friction material although produced by paper making practises these materials are in fact elaborate composite structures which are made up of paper fibre, diatomite, carbon & friction powder. The materials porosity can reach highs of 70%. The production process consists of moulding the compound using heat & pressure, once the resin has solidified the material is blanked from sheet form & bonded to the steel core plate. Once this process is finished the final thicknesses & groove patterns are then machined to the surface. These are typically found in applications such as power shift transmissions & wheel brakes.

The following are properties that are associated with this type of material:

TYPICAL APPLICATIONS Wheel Brakes, Transmissions, Power Shift and Power Take-Off Transmissions

MATING MATERIAL Steel, Cast Steel, Grey Cast Iron

Surface Finish < 0.5μm Ra (20μ”)

FRICTION COEFFICIENT (WET)

Static 0.13 – 0.16

Dynamic 0.11 – 0.14

RECOMMENDED LOAD

Max Dynamic Pressure 3.2 N/mm2 (464 lbf/in2)

Max Rubbing Speed 45 m/s (130 ft/sec)

Max Specific Power 4.0 W/mm2 (3.4 HP/in2)

OIL GROOVING

DIMENSIONS

Friction Thickness 1.5 mm (0.060″) max / 0.40 mm (0.016″) min

Friction Diameter 1,000 mm (39″) max / 50 mm (2″) min

| Material: | Wet paper-based friction materials& Wet paper-based friction disc |

| Raw material (component): | 45-55% fibre (aramid fibre, carbon fibre,composite reinforced fibre, etc.); After the paper is dipped in glue, the glue content is of 23-30%. |

| Size: | Paper width from the automatic paper production line: 600mm Diameter range <=600mm, Paper thickness: 0.6~2.5mm |

| Industrial Standard: | GB/T 13826-2008 Wet type (non-metallic) friction materials GB/T 21955-2008 Tractor and machinery for agriculture and forestry –Paper friction disc– Technical specifications GB/T 37208-2018 Nonmetallic paper based wet type friction materials GB/T 15141-2009 Test method for friction element of wet clutch |

| Applications range: | Engineering machinery: Excavator, Loader, Bulldozer, Paver, Reach stracker, Crane etc. Agricultural and forestry machinery: Tractor, Harvester and corresponding equipments Logistic machinery: Forklift truck, Port logistic machinery Automobile industrial machinery: Reducer, Wet cluth and Wet brake, Motorcycle clutch. |

| OEM and aftermarket | all types of wet paper-based friction disc, such as for Caterpillar, Komatsu, JCB, MF etc. |

The above test data is provided for informational purposes and represents standards in controlled laboratory settings. Actual performance will vary by application and operating conditions.

WhatsApp us

We will contact you within 24 hours, please pay attention to the email with the suffix “@frictiondisc.com”.