We support any form of OEM customization requirements.

We have a 3rd-party QC to guarantee the quality.

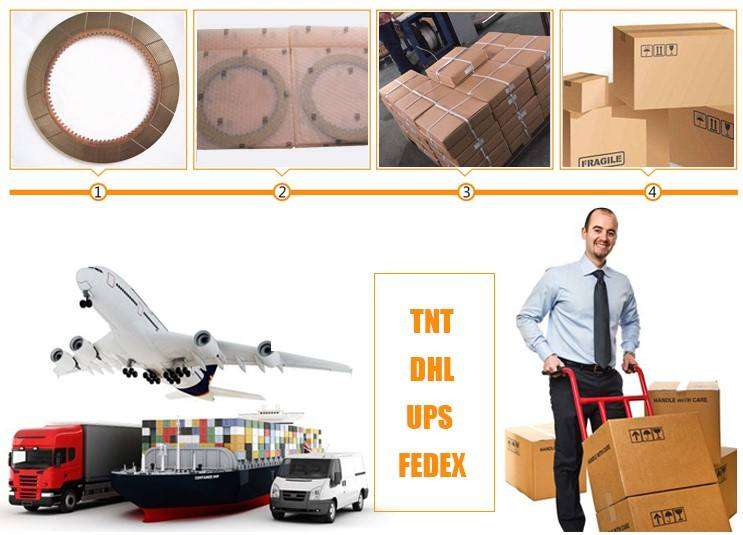

If hurry, we can also send it to you by air at an extra cost.

Support a small amount of customer customization

Contact us 24×7 to solve all your after-sales problems.

Free Sample is available for every clients.

Transmission Friction discs and plates Komatsu® are capable of enduring high amounts of physical stress. We offers heavy duty friction material technology to suit a wide range of Komatsu applications.

Transmission Friction plate and disc for Komatsu Copper-base P/M friction material, friction/brake plate, friction/clutch disc Dry type:

Wet (gumming):

Widely applies in Komatsu construction machinery.

The friction materials dictate the performance of clutches and brakes. They are used in Komatsu tractors, trucks, excavators, wheel loaders and dump-trucks.

TYPICAL APPLICATIONS Wheel Brakes, Transmissions, Power Shift and Power Take-Off Transmissions

MATING MATERIAL Steel, Cast Steel, Grey Cast Iron

Surface Finish < 0.5μm Ra (20μ”)

FRICTION COEFFICIENT (WET)

Static 0.13 – 0.16

Dynamic 0.11 – 0.14

RECOMMENDED LOAD

Max Dynamic Pressure 3.2 N/mm2 (464 lbf/in2)

Max Rubbing Speed 45 m/s (130 ft/sec)

Max Specific Power 4.0 W/mm2 (3.4 HP/in2)

OIL GROOVING

DIMENSIONS

Friction Thickness 1.5 mm (0.060″) max / 0.40 mm (0.016″) min

Friction Diameter 1,000 mm (39″) max / 50 mm (2″) min

In addition to our extensive range of catalogue products, Almax, our quick turnaround custom machined seals department, has the ability to produce an infinite number of profiles using the latest CAD/CAM and CNC machines to produce discs & plates products to the customers’ drawings or by utilizing one of the 100+ computerized profiles as individual pieces or in economical small series.

Many situations in the construction machine require an immediate response and rapid manufacturing and delivery for your urgent repair or prototyping needs. Whether you require a custom profile and material or customized solution of one of our standard profiles, we can ensure the highest quality product at an economical cost due to small batch, lower mold and tooling costs, and minimal manufacturing time. Instances where Almax benefits customers the most are:

Almax products can be manufactured from 5mm to over 700mm (OD) out of a wide range of application-specific specialty elastomers and high performance engineering plastics including:

Submit your specifications and requirements online today, for a custom friction discs & plates quotation.

Checking stock for same or similar friction discs or plates to meet with your requirements.

Getting your samples to design the exact drawing details for your confirmation.

After your confirmation to arrange the first production of sample bushings or pins.

Dispatch samples to you for checking quality or fix the wrong places of discs or plates.

Confirming official order to arrange the bulk producing for first cooperation.

During producing, visit us on product line or take pictures of checking order status.

Finishing producing for inspection by both of us or third party, such SGS etc.

Arranging shipment by sea, train or air. Your feedback will strengthen our cooperation.

WhatsApp us

We will contact you within 24 hours, please pay attention to the email with the suffix “@frictiondisc.com”.